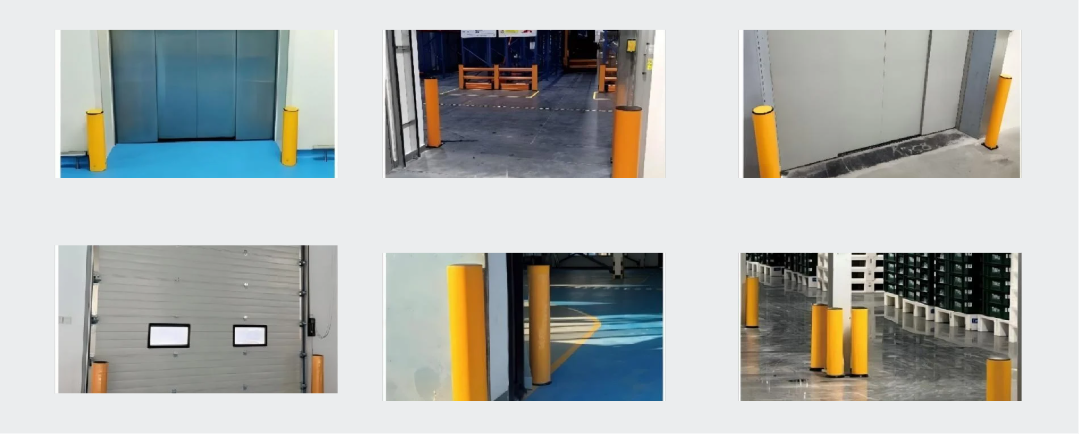

Flexible bollards: suitable for special protection of equipment.

This is a specialized protection system designed for equipment, creating safe zones for both machinery and personnel by shielding them from vehicle impacts. Featuring secondary buffering technology, it can withstand collisions from various types of vehicles and return to its original shape afterward. It is suitable for diverse environmental requirements.

● The eye-catching yellow color provides excellent warning visibility.

● Customizable in different diameters and lengths to meet specific needs.

● Durable and maintenance-free.

| Component | Specification Description |

| Pipe Material | Made from European-imported high-molecular polymers as the base material, blended with high-toughness polymers, antioxidants, UV absorbers, light stabilizers, antistatic agents, nucleating agents, scratch-resistant agents, and more than a dozen internationally certified environmentally friendly materials through polymer modification. |

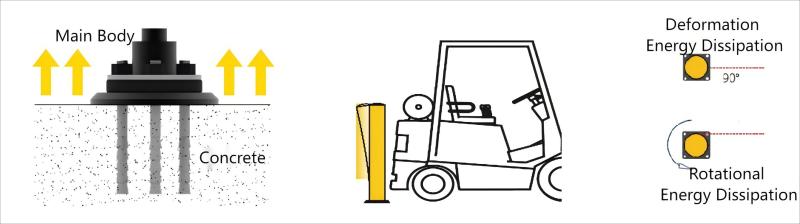

| Base | Assembled from multiple materials including metal and rubber. Exposed metal parts are treated with black spray coating and withstand 500 hours of neutral salt spray testing without rusting. |

| Ground Connection | Custom-designed inverted cone anchor bolts with Dacromet surface treatment, resistant to rust after 1000 hours of neutral salt spray testing. |

| Color | Black RAL 9017 Orange RAL 1003 |

It utilizes uniquely customized adhesive for planted bars. The specialized 10.9-grade anchor bolts can withstand a maximum tensile load of 16 kN.

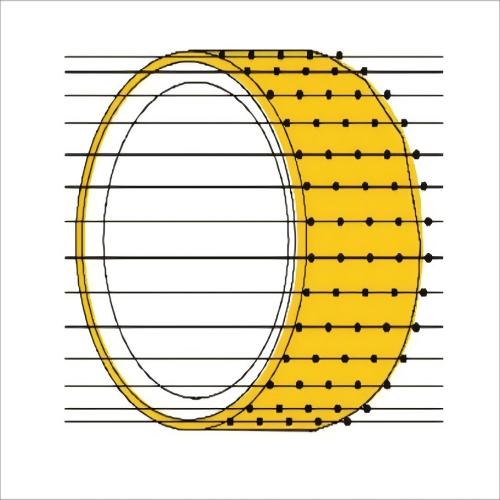

During the manufacturing process, the material is repositioned to establish a unique rebound memory function, enabling the flexible bollard to fully restore its original shape after impact.

Revolutionary Extrusion Technology

· Internally reinforced anti-collision materials

· Externally coated with over ten eco-friendly materials including UV-resistant, antioxidant, anti-static, and scratch-resistant agents

Impact at 45-degree angle: Forklift collides with the bollard at a 45-degree angle, with the rear end striking the edge of the bollard.

Impact at 90-degree angle: Forklift collides with the bollard perpendicularly, with the rear end striking the center of the bollard.

| Impact Energy Absorption (45°) | Impact Energy Absorption (90°) | |||

| LDFACP-90 | Outer diameter: 90mm, Wall thickness: 10mm, Height: Customizable | Internal steel cylinder + rubber buffer | 2.0-ton vehicle at 3 km/h (forklift tail impacts bollard edge) | 2.0-ton vehicle at 2 km/h (forklift tail impacts bollard center) |

| LDFACP-100 | Outer diameter: 100mm, Wall thickness: 10mm, Height: Customizable | Internal steel cylinder + square base + rubber buffer | 2.0-ton vehicle at 3 km/h (forklift tail impacts bollard edge) | 2.0-ton vehicle at 2 km/h (forklift tail impacts bollard center) |

| LDFACP-125Air | Outer diameter: 125mm, Wall thickness: 10mm, Height: Customizable | Internal steel cylinder + rubber buffer | 2.0-ton vehicle at 4 km/h (forklift tail impacts bollard edge) | 2.0-ton vehicle at 3 km/h (forklift tail impacts bollard center) |